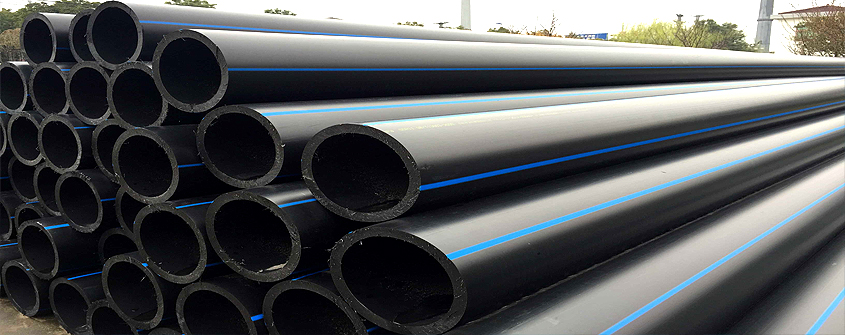

HDPE Pipes

HDPE Pipes

We have developed state-of-the art infrastructure facility that helps in qualitative production of HDPE Pipes ,Our innovative solutions as per the industry standards. Spread on expansive area, our infrastructure assists us in storing, manufacturing, testing and improvising our product range at a smooth and fast pace. Installed with advanced machines and sophisticated technology, our manufacturing unit supports us in customizing the range as per specific requirements of the clients. It also helps to undertake bulk consignments and deliver them in accordance with the industrial standards within given time frame.In line with diverse demands across the globe, we make them available in different sizes, shapes and grades in line with set industry standards for OD 20 mm to 315 mm (In All Grades & Pressure Ratings). To ensure that the customers receive the best quality HDPE Pipes, we test them on several parameters, prior to final dispatch. Buyers can acquire HDPE Pipes at feasible rates, from us.

SPECIFICATIONS

| Size Range | 20mm OD to 630mm OD |

| Size | 20mm to 315mm |

| Unit Length | 6m |

| Standards | IS: 4984-1995 & IS: 14333-1996 |

| Condition | New |

| Material Grade | PE100, PE80, PE63 |

| Pressure Rating | PN-2.5, PN-4.0, PN-6.0, PN-10, PN-12.5, PN-16.0 |

APPLICATIONS

Water Supply Systems :

- Transportation and Distribution system

- House service connection

- Rural, Municipal Water bodies, SEZ’s, Layout’s, etc

Agricultural Systems :

- Column piping for Submersible and Jet Pumps

- Suction and delivery pipes

- Sprinkler and Drip Irrigation systems

- Lift irrigation

- Insecticide spraying

Industrial/Mining Systems :

- Effluents, chemicals and treated/untreated water disposal

- Hydro transport system for handling and conveyance of Iron, Coal and Cement slurry in mines

- For conveyance of edible oil, fruit pulps, juices, milks and other food materials

- As a ventilation and air conditioning duct

Environmental Protection :

- Underground drainage and sewerage application/rehabilitation of existing sewer

- Effluent and waste treatment plants

- Dust suppression piping systems in cement industry

- Sand slurry disposal pipes in dredging

- De-gassing pipes in water effluent marine outfalls

Others :

- Transportation of chemicals, solids, gas and oils

- Underwater pipelines/desalination plants

- Telecommunication cable ducting (PLB Duct.)